Intellectual Property and Standards

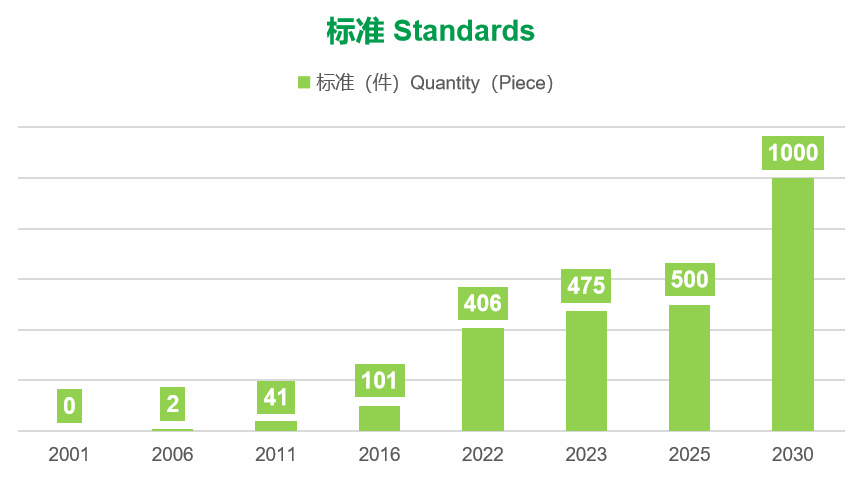

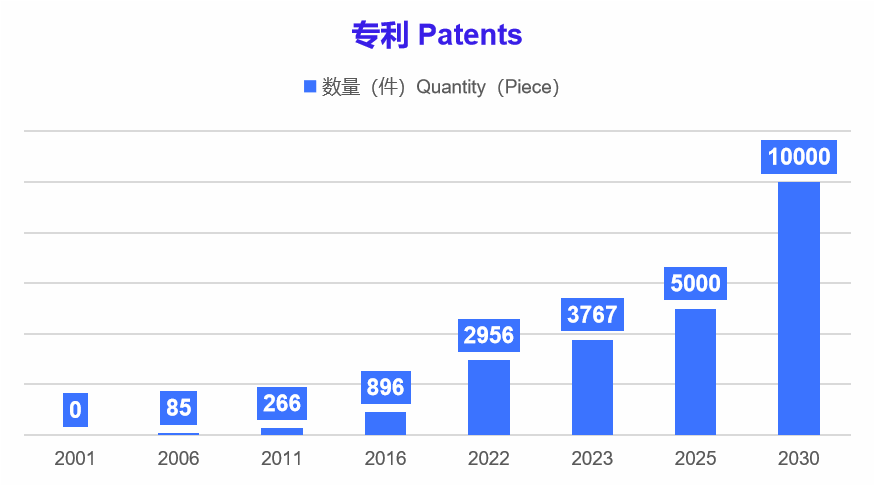

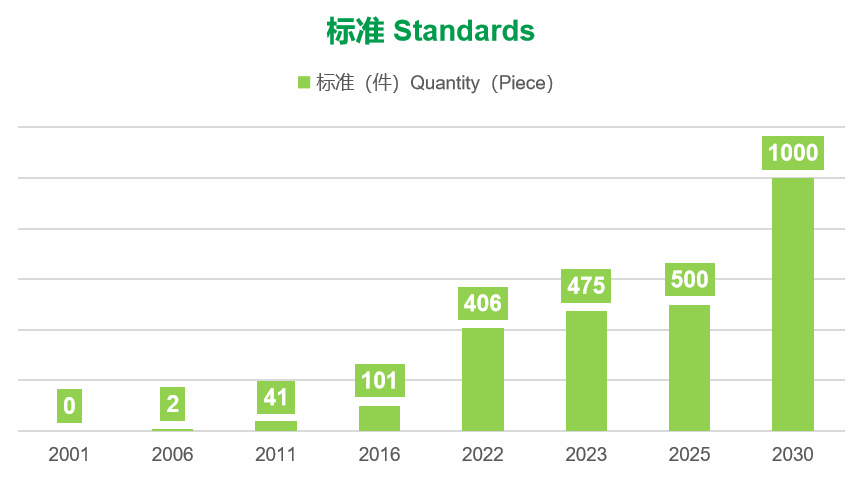

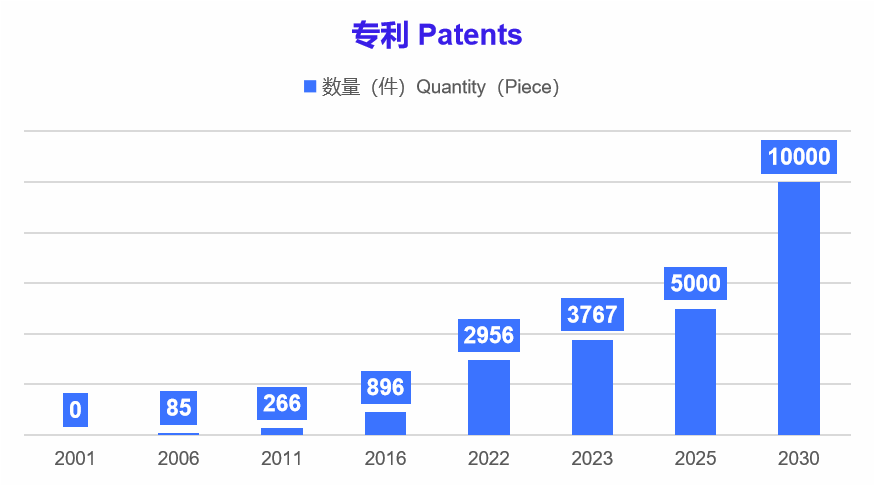

GEM has achieved a number of key technological achievements. As of the end of 2023, GEM has applied for a total of 3767 patents, with 1755 globally authorized and valid patents. It has led/participated in the development and revision of a total of 475 standards, covering more than 10 countries and regions including the United States, Japan, South Korea, the United Kingdom, Germany, France, Italy, Switzerland, Belgium, Sweden, etc. Its core patents rank 233rd in the 2022 Top 500 Chinese Enterprise Patents. GEM and its subsidiaries, QMB and Power Recycling, have registered bulk trademarks overseas to safeguard the development of overseas business.

GEM has twice won the second prize of National Science and Technology Progress Award and received over ten first prizes for provincial and ministerial-level scientific and technological progress awards. GEM's technological innovation capabilities lead the industry. GEM has successfully tackled global technological challenges, developing recycling technologies for used batteries, green treatment of electronic waste, comprehensive resource recovery from scrapped vehicles, and the "core" technologies of ternary materials for power batteries. GEM has made key breakthroughs for China's core technologies and intellectual property system for the green treatment and recycling of typical waste resources, including used batteries, electronic waste, and scrapped vehicles.

GEM's Patents/Standards Multiplication Program