The product introduction

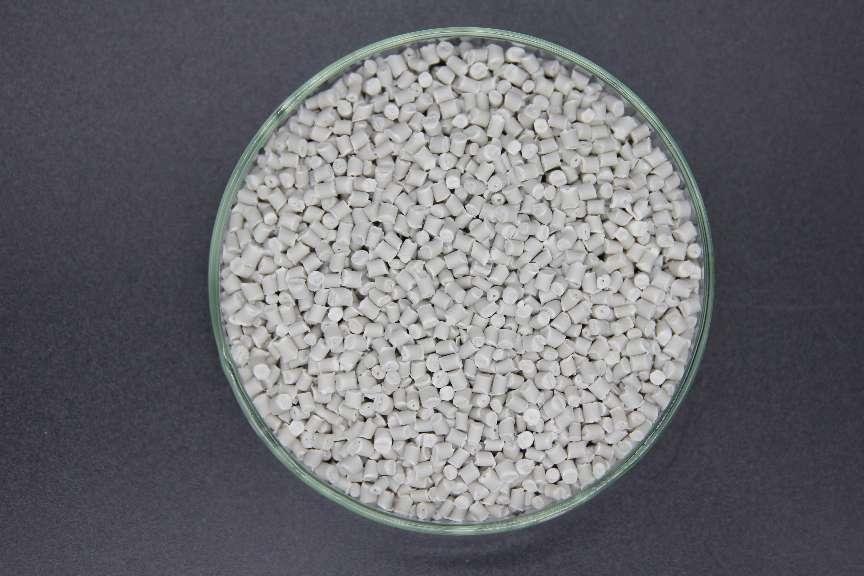

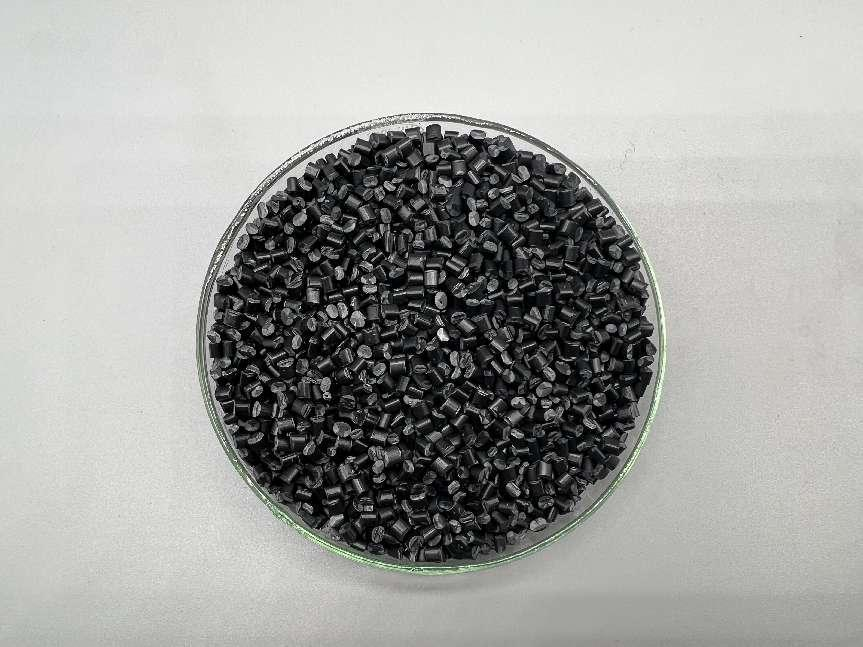

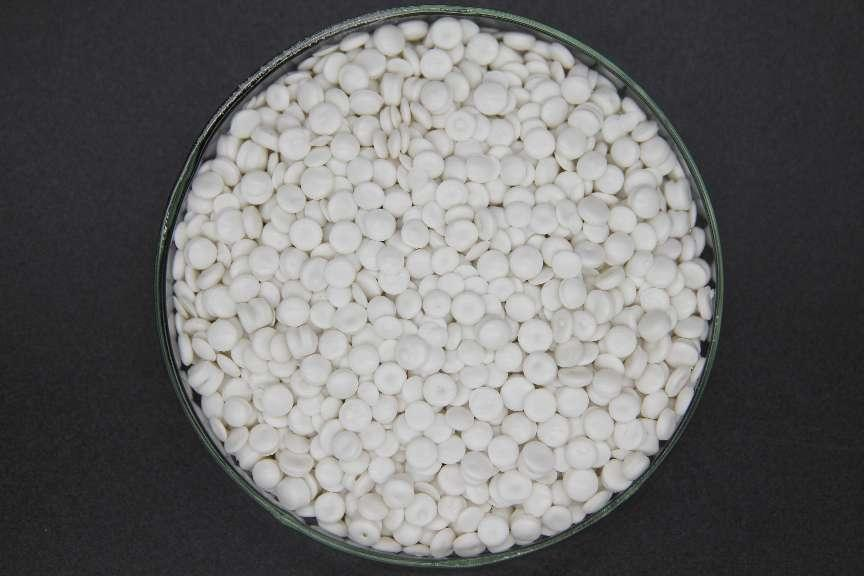

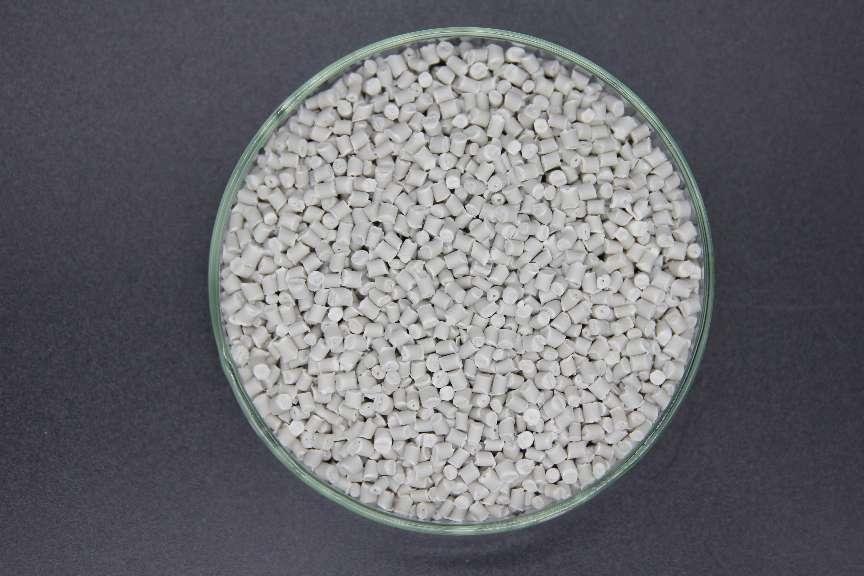

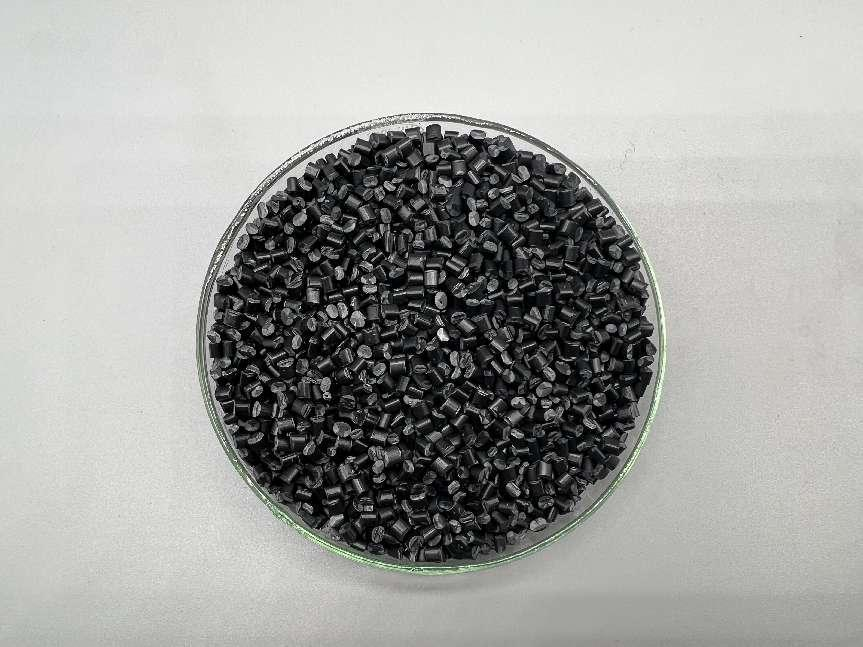

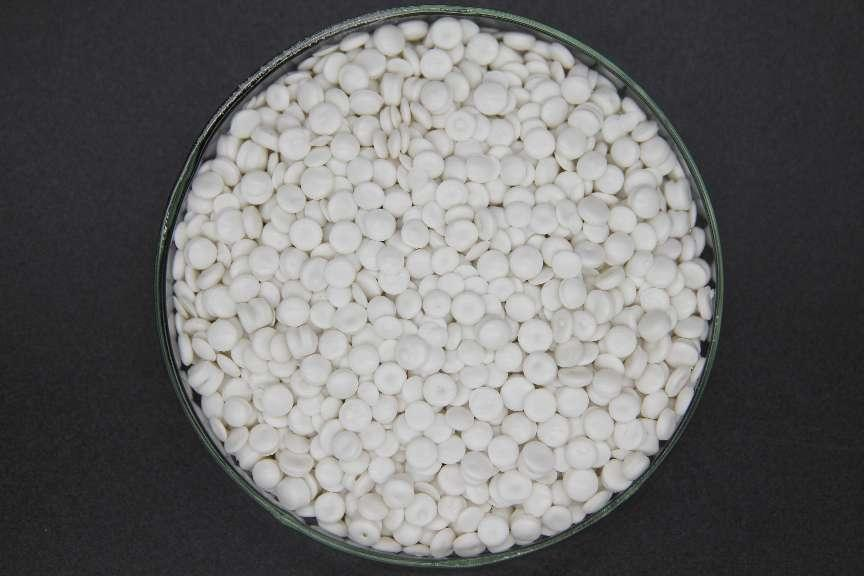

Product Introduction Name: GER High Performance Recycled Modified Plastic Granules r-PP, r-ABS, r-HDPE, r-HIPS, r-PC, r-PMMA , r-LDPE, r-GPPS.

Capacity layout: 2 waste plastic recycling bases, distributed in Fengcheng, Jiangxi and Lankao, Henan, with an annual treatment scale of 70,000 tons of recycled plastics.

Downstream application scenarios: mainly used in five categories: home appliances, automobiles, packaging, home furnishing, building materials.

1)Market Competitive Advantage:

Stable supply of raw materials: Using its own channel advantages, GER focuses on the development of waste plastic resources, deploys six major home appliance dismantling factories, and recycles 50,000 tons of plastic annually;

Intelligent production equipment: The company has more than 50 waste plastic recycling production lines, including multi-stage efficient modified granulation unit, automatic intelligent packaging system, material sorting system, color sorting system, electrostatic sorting system and other clean and efficient production equipment, and has built a waste plastic recycling production line that integrates waste plastic crushing, cleaning, sorting, modification, and regeneration;

Whole system testing equipment: A CNAS accredited laboratory has been established, with complete test and verification conditions, equipped with various world-leading and high-precision testing instruments, which completely cover the physical properties testing of various metals, organics, and materials. The testing items involve RoHS, REACH, California 65. Industry directive standards such as EN71 and POPs provide a reliable guarantee for improving the quality of plastics;

Quality control system: According to the characteristics of recycled plastics, GER has established a six-dimensional evaluation system to standardize the quality management of modified recycled plastics to ensure that all aspects of product performance can meet the standard production, In particular, the purity, odor and other indicators that are particularly important for recycled plastics have increased to a high level of more than 99.5% and below 3.5, which has won the favor of high-end downstream brands.; the company has passed ISO9001, IATF16949, ISO17025 and other quality management system certifications and has achieved long-term effective operation. At the same time, the company's products have also passed GRS (Global Recycling management system), ISCC PLUS (International Sustainability & Carbon Certification) and other sustainable development certifications, which provide a strong guarantee for the company to continue to produce traceable high-quality recycled plastic products.

Main Customers: There are mainly domestic modified listed enterprises such as: Orinko, Polyrocks, Julong, Hechang. International petrochemical giants: INEOS Styrolution, Mitsui Plastic, LyondellBasell、ExxonMobil、Borouge etc., international and domestic well-known brand owners: LEXY, M&G, Schick etc., and domestic terminal injection molding processing enterprises.

Sales in the past three years:

2019: 273,826,337.06 Yuan

2020: 243,938,550.01 Yuan

2021: 288,131,845.50 Yuan

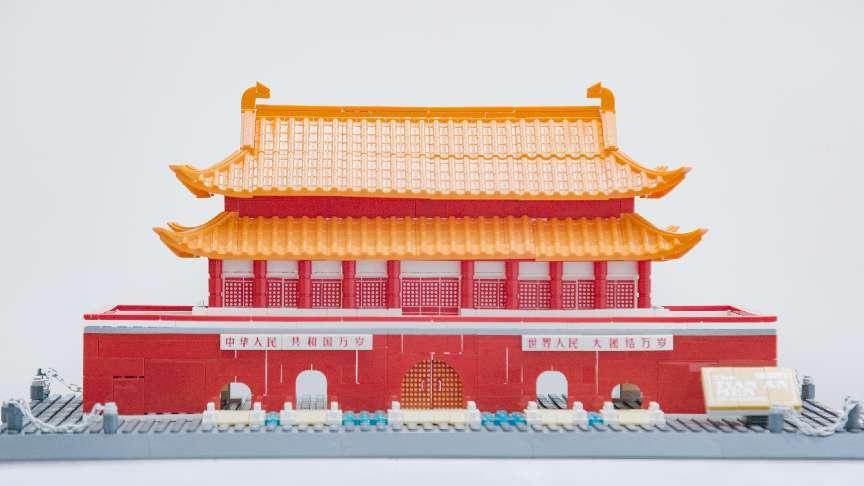

Hunan Park - Plastic Wood

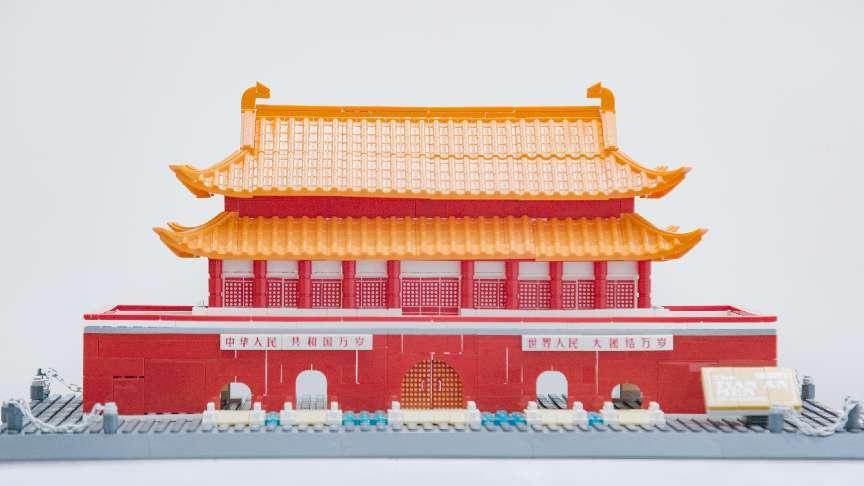

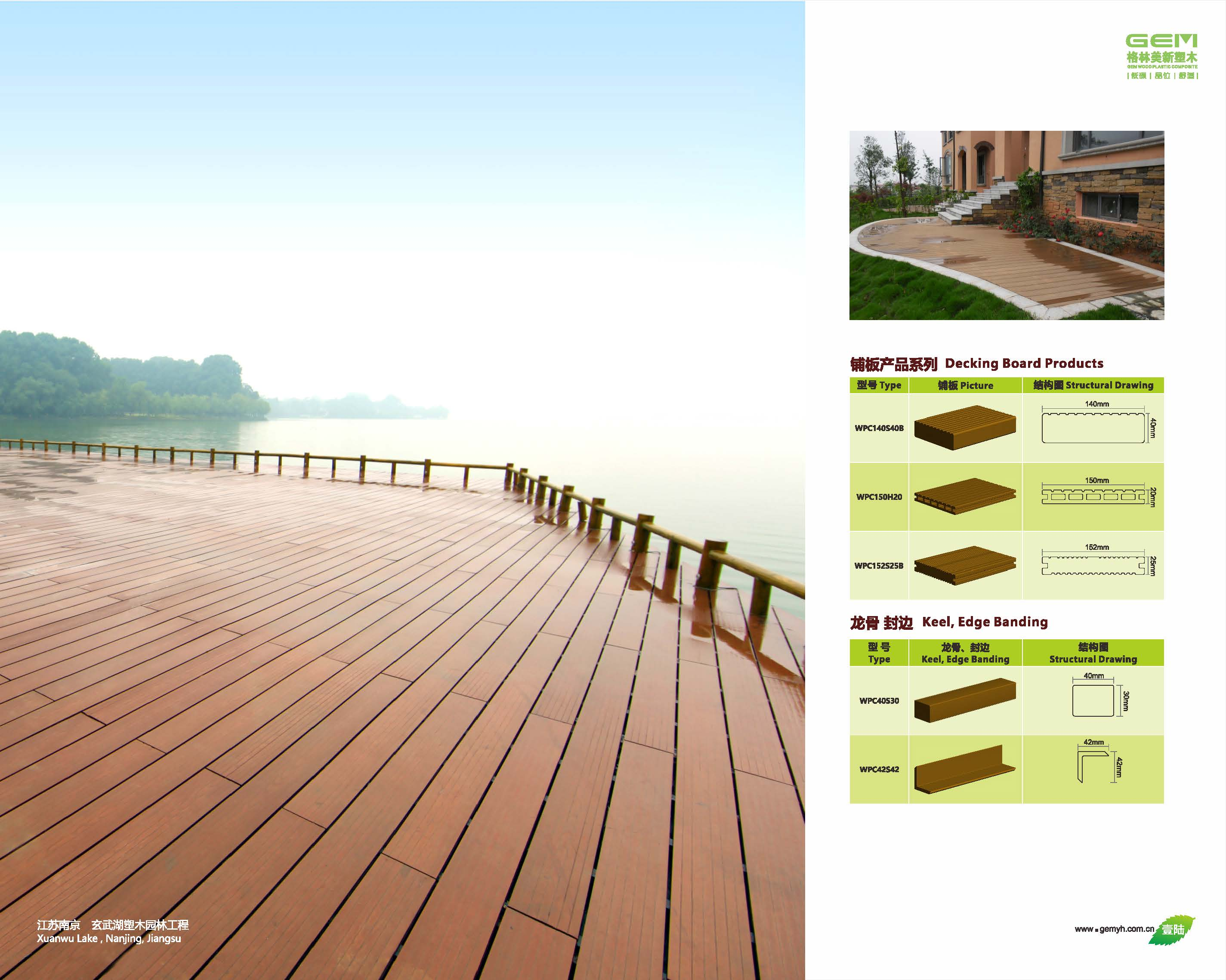

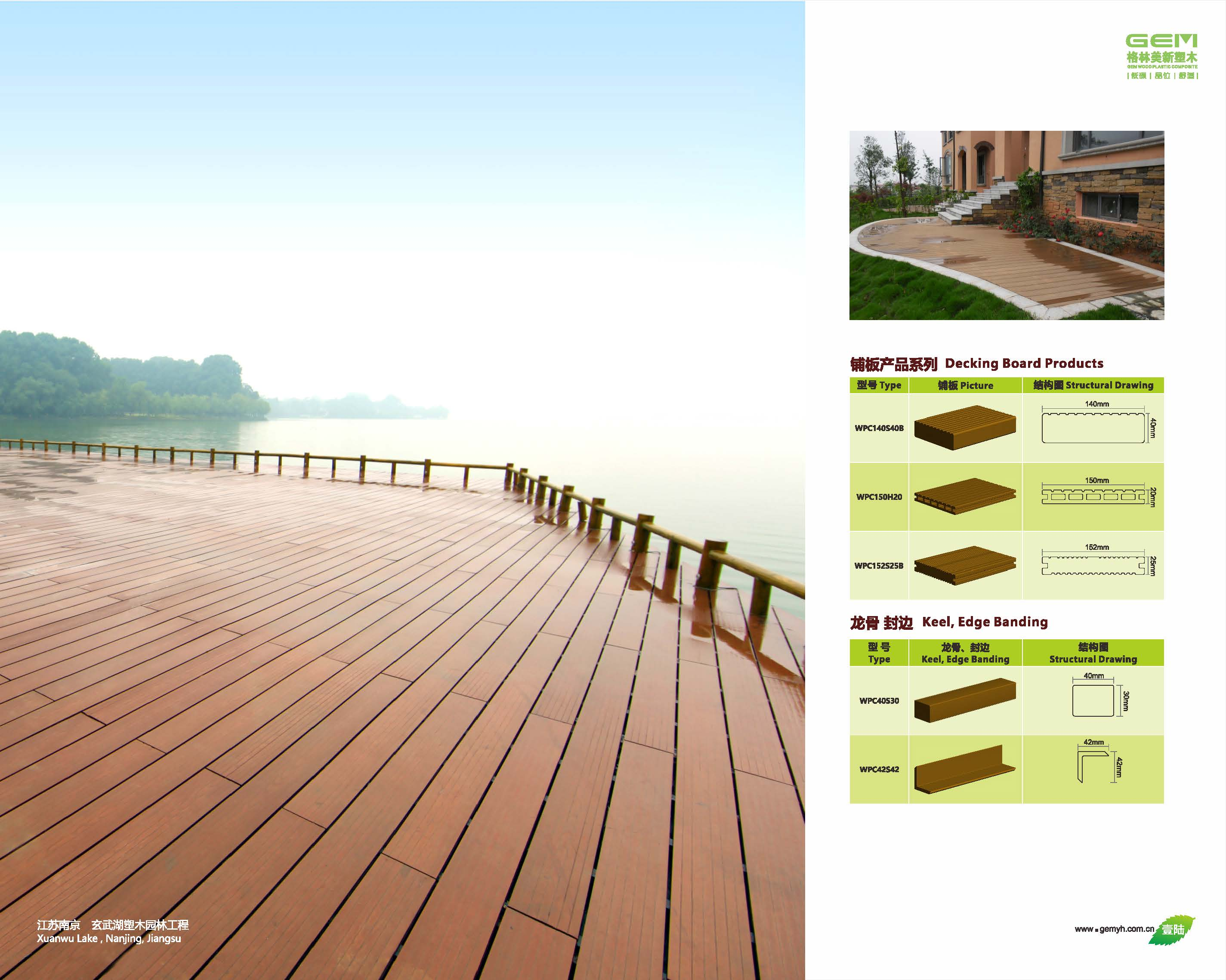

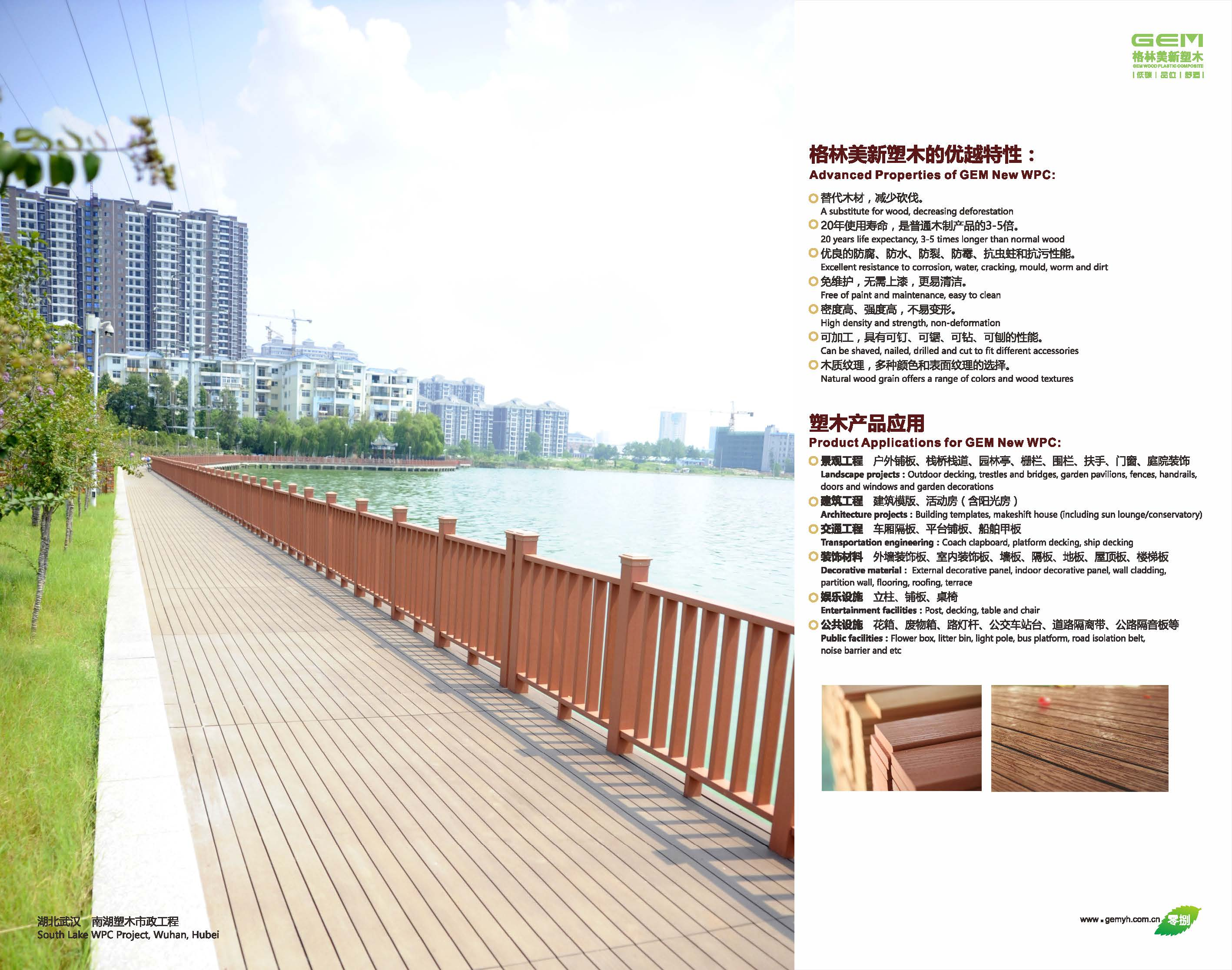

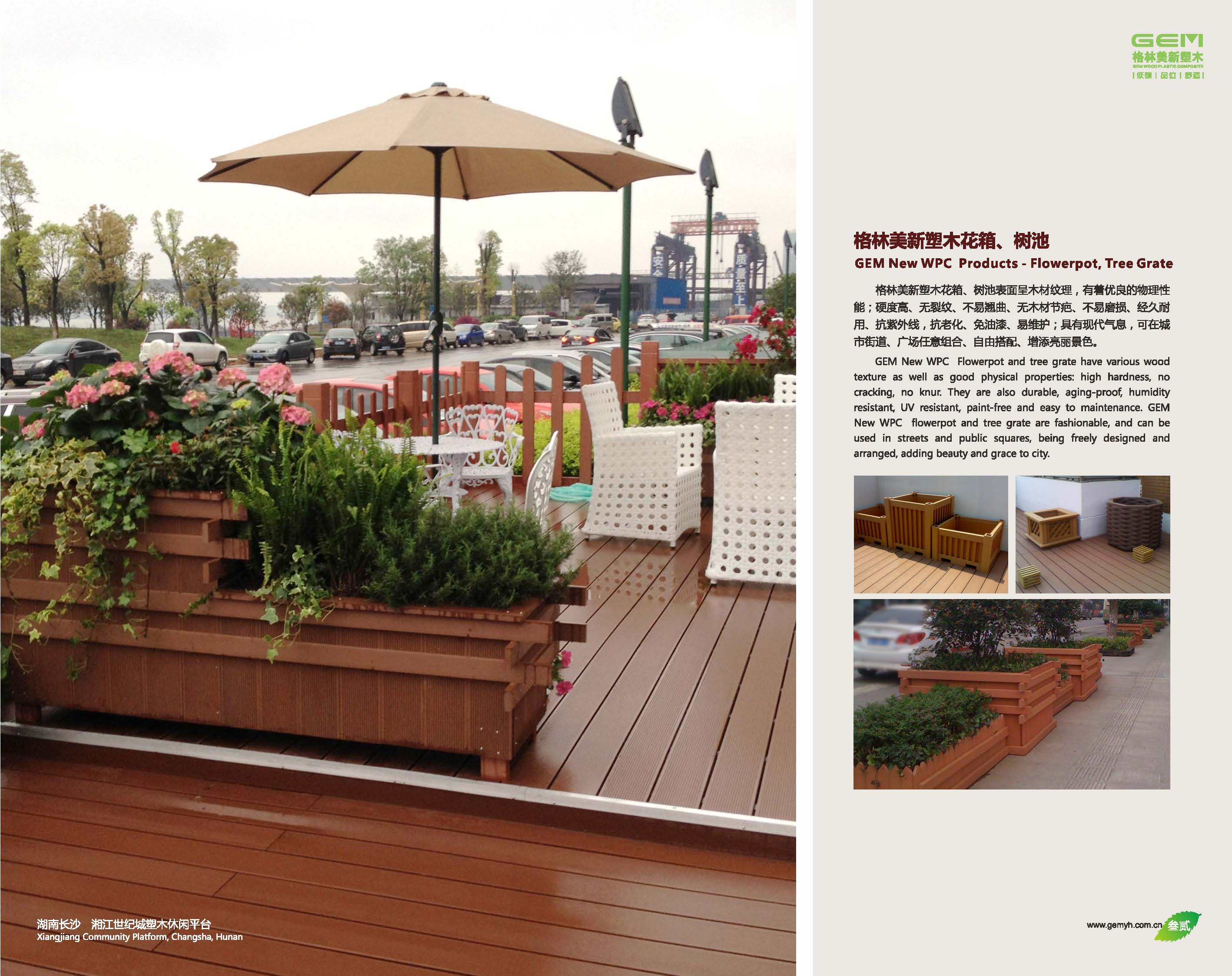

1、Product Introduction: GEM Plastic Wood Series (Plastic Wood Floor / Plastic Wood Guardrail / Plastic Wood Bench Chair / Plastic Wood Flower Box, Flower Rack / Plastic Wood Pavilion / Plastic Wood Table and Chair / Plastic Wood Trash Can, etc.)

Production capacity: 50,000 tons / year (Hunan Xinhua).

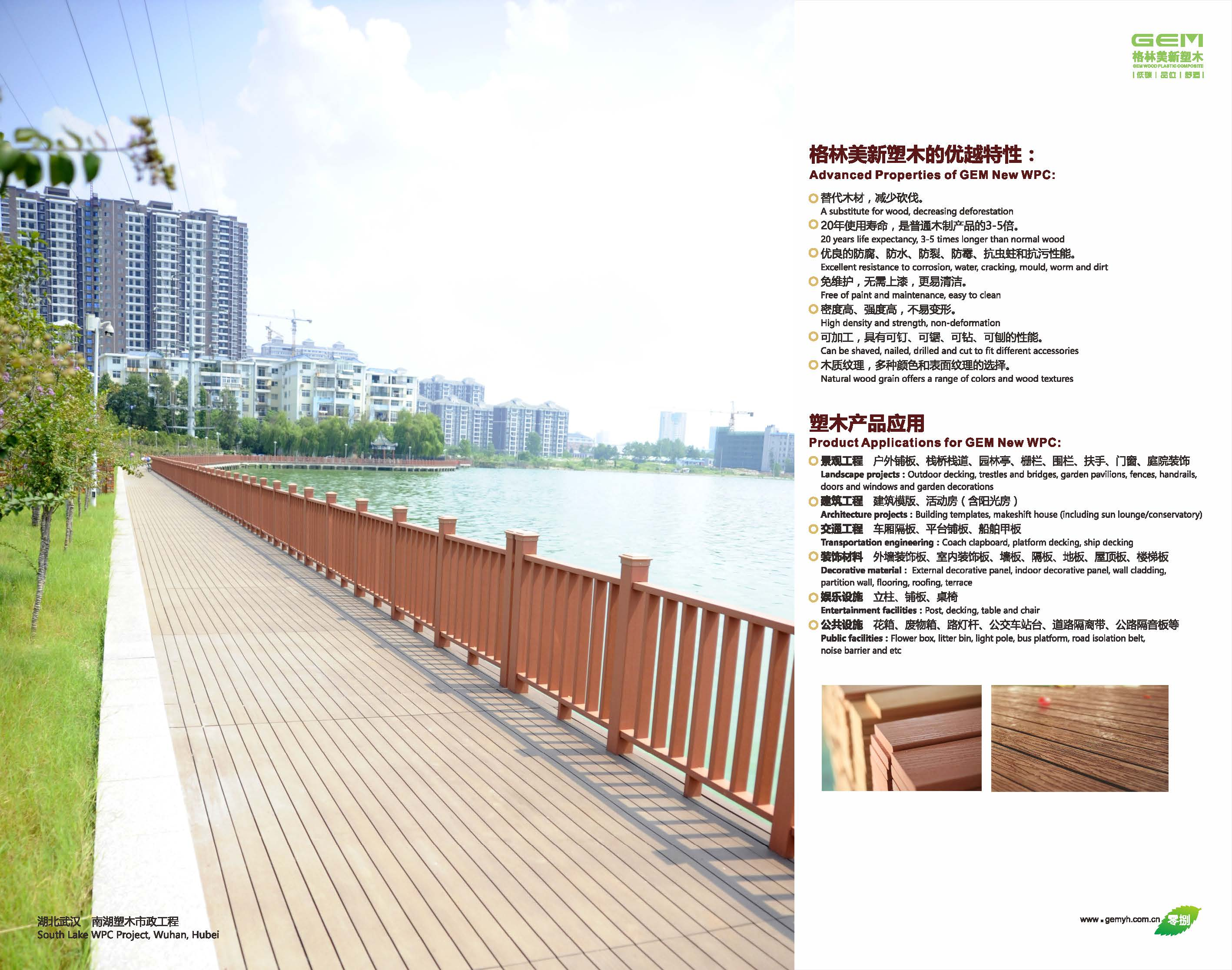

Downstream application scenarios: GEM plastic wood is widely used in various indoor and outdoor places, tourist attractions, garden landscapes, sanitation facilities, municipal engineering, and other projects, is an ideal substitute for natural wood, and has become a green and low-carbon product favored by the market.

(1)floor

(2)guardrail

(3)Stool chair

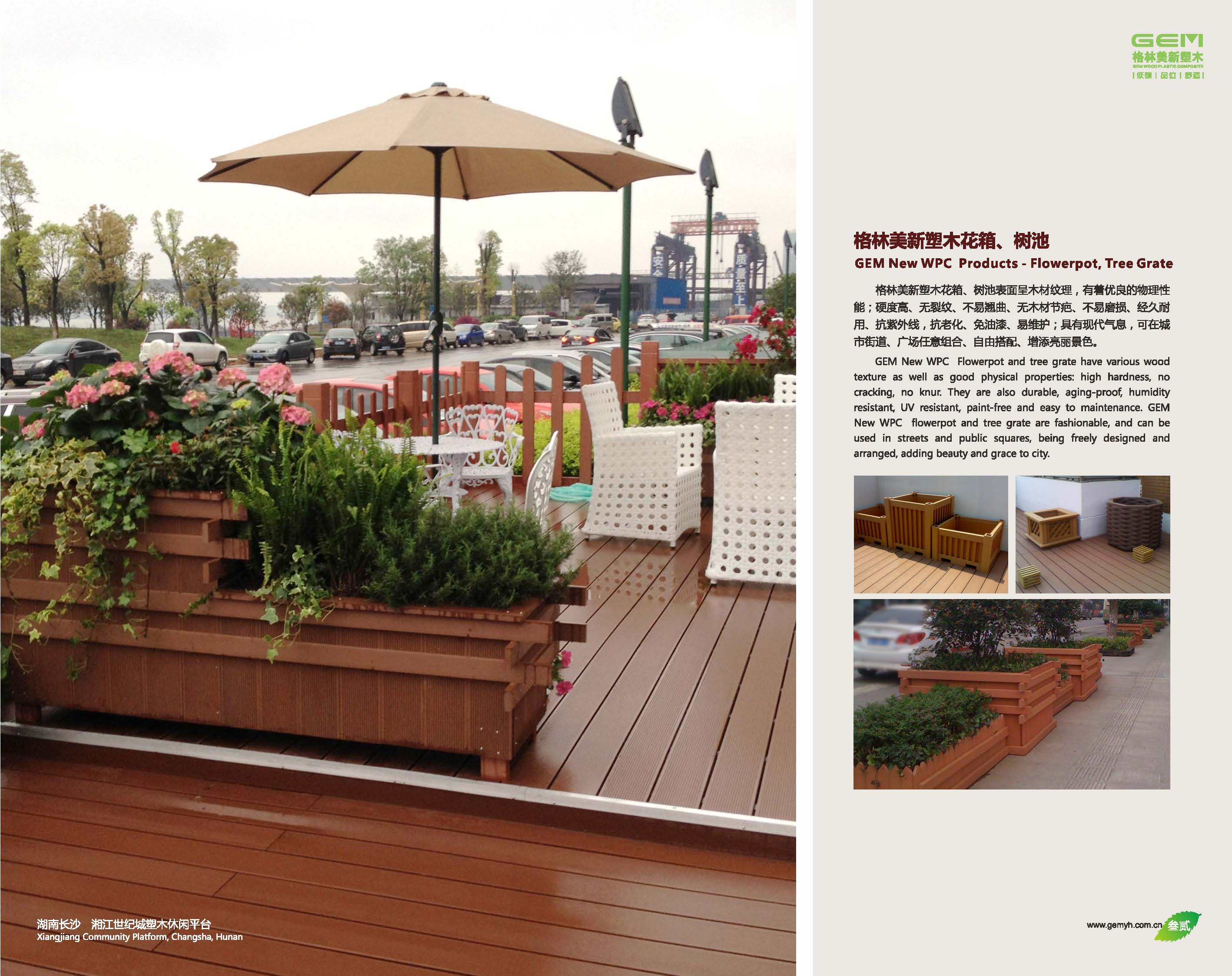

(4)Flower box

Figure 1 Base rendering

2. Market situation (market competitive advantage, major customers, sales in the past three years).

(1) Market competitive advantageRecycled plastic raw material resources are self-sufficient, with raw material cost advantages; Advanced automated production line to ensure product quality stability; Comprehensive testing and equipment configuration to ensure the continuous development of product technology; The strong design team ensures the timely introduction of molded wood product models and integrated products.

(2)Main customers: foreign markets: products are exported to more than 10 countries in Europe, America, Southeast Asia, etc., the main customers are Machine&Computer World Inc. etc. Best-selling in more than 10 provinces in China, the main customers are Guangdong Nanyue, Country Garden, Poly, Shenzhen Sambo-wpc, YCIH, CEG, Jingmen Coco, Hubei Changtai, Changsha Yiwei.

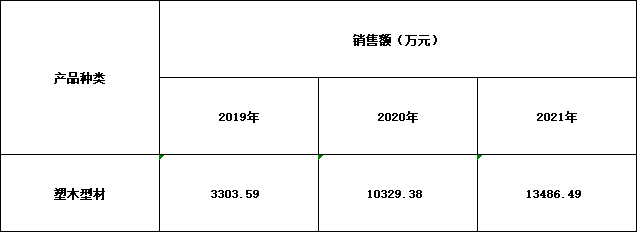

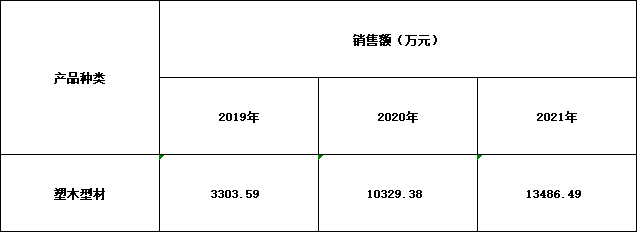

(3) Sales in the past 3 years:

Product Sales (10,000 Yuan)

Plastic Wood