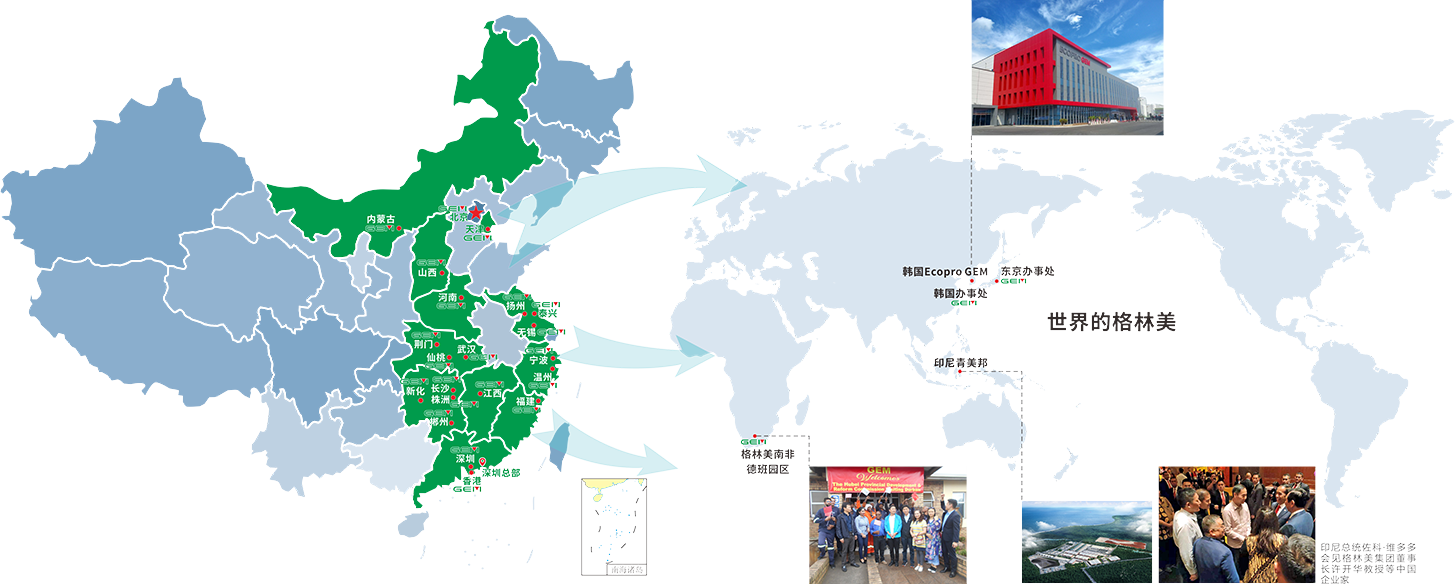

十九年来,格林美一直践行“资源有限、循环无限”的产业理念,潜心开发先进的循环技术,不断扩大废物处理规模,在广东、湖北、湖南、江西、河南、山西、内蒙古、浙江、江苏、天津、福建十一省与直辖市建成16大循环产业园,纵横3000公里,与5亿人建立废物处理合作关系,年处理废物总量400万吨以上,构建了废旧电池与钴镍钨稀有金属废弃物循环利用、电子废弃物循环利用与报废汽车循环利用三大核心循环产业群以及超细钴镍钨粉末材料与镍钴化学品、锂离子电池材料与三元动力电池材料两大世界级产品链。辐射世界,投资南非、印尼、韩国,创造中国企业对接“一带一路”倡议的绿色产业模式,积极参与全球废物循环利用产业合作,努力创建21世纪的伟大环保企业。

香港新创资源再生有限公司位于内蒙古自治区鄂尔多斯市达拉特经济开发区,成立于2014年3月,现为格林美股份有限公司的控股孙公司。注册资金962.786万元,内蒙古新创资源再生有限公司电子废弃物集中处理项目于2013年10月列入自治区废弃电器电子产品集中处理发展规划。2014年10月通过鄂尔多斯市环境保护局建设项目环境保护验收和废弃电器电子产品处理企业资格审查取得处理资格证书。并于2015年8月被纳入国家基金补贴名单。

总投资9000余万元,占地76.5亩,2015年10月一期项目投产使用,2017年1月二期项目开始投入使用。

公司位于呼和浩特市、包头市、鄂尔多斯市“金三角”开发区中心地带,辐射内蒙主要人口密集区与工业密集区,与格林美位于河南兰考到山西长治的电子废弃物基地形成从中原到西北部的回收链,强化格林美在中原与西北部报废电子电器回收利用的核心地位竞争力与盈利能力。

深圳新创资源再生有限公司位于内蒙古自治区鄂尔多斯市达拉特经济开发区,成立于2014年3月,现为格林美股份有限公司的控股孙公司。注册资金962.786万元,内蒙古新创资源再生有限公司电子废弃物集中处理项目于2013年10月列入自治区废弃电器电子产品集中处理发展规划。2014年10月通过鄂尔多斯市环境保护局建设项目环境保护验收和废弃电器电子产品处理企业资格审查取得处理资格证书。并于2015年8月被纳入国家基金补贴名单。

总投资9000余万元,占地76.5亩,2015年10月一期项目投产使用,2017年1月二期项目开始投入使用。

公司位于呼和浩特市、包头市、鄂尔多斯市“金三角”开发区中心地带,辐射内蒙主要人口密集区与工业密集区,与格林美位于河南兰考到山西长治的电子废弃物基地形成从中原到西北部的回收链,强化格林美在中原与西北部报废电子电器回收利用的核心地位竞争力与盈利能力。

福建新创资源再生有限公司位于内蒙古自治区鄂尔多斯市达拉特经济开发区,成立于2014年3月,现为格林美股份有限公司的控股孙公司。注册资金962.786万元,内蒙古新创资源再生有限公司电子废弃物集中处理项目于2013年10月列入自治区废弃电器电子产品集中处理发展规划。2014年10月通过鄂尔多斯市环境保护局建设项目环境保护验收和废弃电器电子产品处理企业资格审查取得处理资格证书。并于2015年8月被纳入国家基金补贴名单。

总投资9000余万元,占地76.5亩,2015年10月一期项目投产使用,2017年1月二期项目开始投入使用。

公司位于呼和浩特市、包头市、鄂尔多斯市“金三角”开发区中心地带,辐射内蒙主要人口密集区与工业密集区,与格林美位于河南兰考到山西长治的电子废弃物基地形成从中原到西北部的回收链,强化格林美在中原与西北部报废电子电器回收利用的核心地位竞争力与盈利能力。

江西新创资源再生有限公司位于内蒙古自治区鄂尔多斯市达拉特经济开发区,成立于2014年3月,现为格林美股份有限公司的控股孙公司。注册资金962.786万元,内蒙古新创资源再生有限公司电子废弃物集中处理项目于2013年10月列入自治区废弃电器电子产品集中处理发展规划。2014年10月通过鄂尔多斯市环境保护局建设项目环境保护验收和废弃电器电子产品处理企业资格审查取得处理资格证书。并于2015年8月被纳入国家基金补贴名单。

总投资9000余万元,占地76.5亩,2015年10月一期项目投产使用,2017年1月二期项目开始投入使用。

公司位于呼和浩特市、包头市、鄂尔多斯市“金三角”开发区中心地带,辐射内蒙主要人口密集区与工业密集区,与格林美位于河南兰考到山西长治的电子废弃物基地形成从中原到西北部的回收链,强化格林美在中原与西北部报废电子电器回收利用的核心地位竞争力与盈利能力。

郴州新创资源再生有限公司位于内蒙古自治区鄂尔多斯市达拉特经济开发区,成立于2014年3月,现为格林美股份有限公司的控股孙公司。注册资金962.786万元,内蒙古新创资源再生有限公司电子废弃物集中处理项目于2013年10月列入自治区废弃电器电子产品集中处理发展规划。2014年10月通过鄂尔多斯市环境保护局建设项目环境保护验收和废弃电器电子产品处理企业资格审查取得处理资格证书。并于2015年8月被纳入国家基金补贴名单。

总投资9000余万元,占地76.5亩,2015年10月一期项目投产使用,2017年1月二期项目开始投入使用。

公司位于呼和浩特市、包头市、鄂尔多斯市“金三角”开发区中心地带,辐射内蒙主要人口密集区与工业密集区,与格林美位于河南兰考到山西长治的电子废弃物基地形成从中原到西北部的回收链,强化格林美在中原与西北部报废电子电器回收利用的核心地位竞争力与盈利能力。

株洲新创资源再生有限公司位于内蒙古自治区鄂尔多斯市达拉特经济开发区,成立于2014年3月,现为格林美股份有限公司的控股孙公司。注册资金962.786万元,内蒙古新创资源再生有限公司电子废弃物集中处理项目于2013年10月列入自治区废弃电器电子产品集中处理发展规划。2014年10月通过鄂尔多斯市环境保护局建设项目环境保护验收和废弃电器电子产品处理企业资格审查取得处理资格证书。并于2015年8月被纳入国家基金补贴名单。

总投资9000余万元,占地76.5亩,2015年10月一期项目投产使用,2017年1月二期项目开始投入使用。

公司位于呼和浩特市、包头市、鄂尔多斯市“金三角”开发区中心地带,辐射内蒙主要人口密集区与工业密集区,与格林美位于河南兰考到山西长治的电子废弃物基地形成从中原到西北部的回收链,强化格林美在中原与西北部报废电子电器回收利用的核心地位竞争力与盈利能力。

长沙新创资源再生有限公司位于内蒙古自治区鄂尔多斯市达拉特经济开发区,成立于2014年3月,现为格林美股份有限公司的控股孙公司。注册资金962.786万元,内蒙古新创资源再生有限公司电子废弃物集中处理项目于2013年10月列入自治区废弃电器电子产品集中处理发展规划。2014年10月通过鄂尔多斯市环境保护局建设项目环境保护验收和废弃电器电子产品处理企业资格审查取得处理资格证书。并于2015年8月被纳入国家基金补贴名单。

总投资9000余万元,占地76.5亩,2015年10月一期项目投产使用,2017年1月二期项目开始投入使用。

公司位于呼和浩特市、包头市、鄂尔多斯市“金三角”开发区中心地带,辐射内蒙主要人口密集区与工业密集区,与格林美位于河南兰考到山西长治的电子废弃物基地形成从中原到西北部的回收链,强化格林美在中原与西北部报废电子电器回收利用的核心地位竞争力与盈利能力。

新化新创资源再生有限公司位于内蒙古自治区鄂尔多斯市达拉特经济开发区,成立于2014年3月,现为格林美股份有限公司的控股孙公司。注册资金962.786万元,内蒙古新创资源再生有限公司电子废弃物集中处理项目于2013年10月列入自治区废弃电器电子产品集中处理发展规划。2014年10月通过鄂尔多斯市环境保护局建设项目环境保护验收和废弃电器电子产品处理企业资格审查取得处理资格证书。并于2015年8月被纳入国家基金补贴名单。

总投资9000余万元,占地76.5亩,2015年10月一期项目投产使用,2017年1月二期项目开始投入使用。

公司位于呼和浩特市、包头市、鄂尔多斯市“金三角”开发区中心地带,辐射内蒙主要人口密集区与工业密集区,与格林美位于河南兰考到山西长治的电子废弃物基地形成从中原到西北部的回收链,强化格林美在中原与西北部报废电子电器回收利用的核心地位竞争力与盈利能力。

温州新创资源再生有限公司位于内蒙古自治区鄂尔多斯市达拉特经济开发区,成立于2014年3月,现为格林美股份有限公司的控股孙公司。注册资金962.786万元,内蒙古新创资源再生有限公司电子废弃物集中处理项目于2013年10月列入自治区废弃电器电子产品集中处理发展规划。2014年10月通过鄂尔多斯市环境保护局建设项目环境保护验收和废弃电器电子产品处理企业资格审查取得处理资格证书。并于2015年8月被纳入国家基金补贴名单。

总投资9000余万元,占地76.5亩,2015年10月一期项目投产使用,2017年1月二期项目开始投入使用。

公司位于呼和浩特市、包头市、鄂尔多斯市“金三角”开发区中心地带,辐射内蒙主要人口密集区与工业密集区,与格林美位于河南兰考到山西长治的电子废弃物基地形成从中原到西北部的回收链,强化格林美在中原与西北部报废电子电器回收利用的核心地位竞争力与盈利能力。

宁波新创资源再生有限公司位于内蒙古自治区鄂尔多斯市达拉特经济开发区,成立于2014年3月,现为格林美股份有限公司的控股孙公司。注册资金962.786万元,内蒙古新创资源再生有限公司电子废弃物集中处理项目于2013年10月列入自治区废弃电器电子产品集中处理发展规划。2014年10月通过鄂尔多斯市环境保护局建设项目环境保护验收和废弃电器电子产品处理企业资格审查取得处理资格证书。并于2015年8月被纳入国家基金补贴名单。

总投资9000余万元,占地76.5亩,2015年10月一期项目投产使用,2017年1月二期项目开始投入使用。

公司位于呼和浩特市、包头市、鄂尔多斯市“金三角”开发区中心地带,辐射内蒙主要人口密集区与工业密集区,与格林美位于河南兰考到山西长治的电子废弃物基地形成从中原到西北部的回收链,强化格林美在中原与西北部报废电子电器回收利用的核心地位竞争力与盈利能力。

武汉新创资源再生有限公司位于内蒙古自治区鄂尔多斯市达拉特经济开发区,成立于2014年3月,现为格林美股份有限公司的控股孙公司。注册资金962.786万元,内蒙古新创资源再生有限公司电子废弃物集中处理项目于2013年10月列入自治区废弃电器电子产品集中处理发展规划。2014年10月通过鄂尔多斯市环境保护局建设项目环境保护验收和废弃电器电子产品处理企业资格审查取得处理资格证书。并于2015年8月被纳入国家基金补贴名单。

总投资9000余万元,占地76.5亩,2015年10月一期项目投产使用,2017年1月二期项目开始投入使用。

公司位于呼和浩特市、包头市、鄂尔多斯市“金三角”开发区中心地带,辐射内蒙主要人口密集区与工业密集区,与格林美位于河南兰考到山西长治的电子废弃物基地形成从中原到西北部的回收链,强化格林美在中原与西北部报废电子电器回收利用的核心地位竞争力与盈利能力。

仙桃新创资源再生有限公司位于内蒙古自治区鄂尔多斯市达拉特经济开发区,成立于2014年3月,现为格林美股份有限公司的控股孙公司。注册资金962.786万元,内蒙古新创资源再生有限公司电子废弃物集中处理项目于2013年10月列入自治区废弃电器电子产品集中处理发展规划。2014年10月通过鄂尔多斯市环境保护局建设项目环境保护验收和废弃电器电子产品处理企业资格审查取得处理资格证书。并于2015年8月被纳入国家基金补贴名单。

总投资9000余万元,占地76.5亩,2015年10月一期项目投产使用,2017年1月二期项目开始投入使用。

公司位于呼和浩特市、包头市、鄂尔多斯市“金三角”开发区中心地带,辐射内蒙主要人口密集区与工业密集区,与格林美位于河南兰考到山西长治的电子废弃物基地形成从中原到西北部的回收链,强化格林美在中原与西北部报废电子电器回收利用的核心地位竞争力与盈利能力。

荆门新创资源再生有限公司位于内蒙古自治区鄂尔多斯市达拉特经济开发区,成立于2014年3月,现为格林美股份有限公司的控股孙公司。注册资金962.786万元,内蒙古新创资源再生有限公司电子废弃物集中处理项目于2013年10月列入自治区废弃电器电子产品集中处理发展规划。2014年10月通过鄂尔多斯市环境保护局建设项目环境保护验收和废弃电器电子产品处理企业资格审查取得处理资格证书。并于2015年8月被纳入国家基金补贴名单。

总投资9000余万元,占地76.5亩,2015年10月一期项目投产使用,2017年1月二期项目开始投入使用。

公司位于呼和浩特市、包头市、鄂尔多斯市“金三角”开发区中心地带,辐射内蒙主要人口密集区与工业密集区,与格林美位于河南兰考到山西长治的电子废弃物基地形成从中原到西北部的回收链,强化格林美在中原与西北部报废电子电器回收利用的核心地位竞争力与盈利能力。

无锡新创资源再生有限公司位于内蒙古自治区鄂尔多斯市达拉特经济开发区,成立于2014年3月,现为格林美股份有限公司的控股孙公司。注册资金962.786万元,内蒙古新创资源再生有限公司电子废弃物集中处理项目于2013年10月列入自治区废弃电器电子产品集中处理发展规划。2014年10月通过鄂尔多斯市环境保护局建设项目环境保护验收和废弃电器电子产品处理企业资格审查取得处理资格证书。并于2015年8月被纳入国家基金补贴名单。

总投资9000余万元,占地76.5亩,2015年10月一期项目投产使用,2017年1月二期项目开始投入使用。

公司位于呼和浩特市、包头市、鄂尔多斯市“金三角”开发区中心地带,辐射内蒙主要人口密集区与工业密集区,与格林美位于河南兰考到山西长治的电子废弃物基地形成从中原到西北部的回收链,强化格林美在中原与西北部报废电子电器回收利用的核心地位竞争力与盈利能力。

泰兴新创资源再生有限公司位于内蒙古自治区鄂尔多斯市达拉特经济开发区,成立于2014年3月,现为格林美股份有限公司的控股孙公司。注册资金962.786万元,内蒙古新创资源再生有限公司电子废弃物集中处理项目于2013年10月列入自治区废弃电器电子产品集中处理发展规划。2014年10月通过鄂尔多斯市环境保护局建设项目环境保护验收和废弃电器电子产品处理企业资格审查取得处理资格证书。并于2015年8月被纳入国家基金补贴名单。

总投资9000余万元,占地76.5亩,2015年10月一期项目投产使用,2017年1月二期项目开始投入使用。

公司位于呼和浩特市、包头市、鄂尔多斯市“金三角”开发区中心地带,辐射内蒙主要人口密集区与工业密集区,与格林美位于河南兰考到山西长治的电子废弃物基地形成从中原到西北部的回收链,强化格林美在中原与西北部报废电子电器回收利用的核心地位竞争力与盈利能力。

扬州新创资源再生有限公司位于内蒙古自治区鄂尔多斯市达拉特经济开发区,成立于2014年3月,现为格林美股份有限公司的控股孙公司。注册资金962.786万元,内蒙古新创资源再生有限公司电子废弃物集中处理项目于2013年10月列入自治区废弃电器电子产品集中处理发展规划。2014年10月通过鄂尔多斯市环境保护局建设项目环境保护验收和废弃电器电子产品处理企业资格审查取得处理资格证书。并于2015年8月被纳入国家基金补贴名单。

总投资9000余万元,占地76.5亩,2015年10月一期项目投产使用,2017年1月二期项目开始投入使用。

公司位于呼和浩特市、包头市、鄂尔多斯市“金三角”开发区中心地带,辐射内蒙主要人口密集区与工业密集区,与格林美位于河南兰考到山西长治的电子废弃物基地形成从中原到西北部的回收链,强化格林美在中原与西北部报废电子电器回收利用的核心地位竞争力与盈利能力。

山西新创资源再生有限公司位于内蒙古自治区鄂尔多斯市达拉特经济开发区,成立于2014年3月,现为格林美股份有限公司的控股孙公司。注册资金962.786万元,内蒙古新创资源再生有限公司电子废弃物集中处理项目于2013年10月列入自治区废弃电器电子产品集中处理发展规划。2014年10月通过鄂尔多斯市环境保护局建设项目环境保护验收和废弃电器电子产品处理企业资格审查取得处理资格证书。并于2015年8月被纳入国家基金补贴名单。

总投资9000余万元,占地76.5亩,2015年10月一期项目投产使用,2017年1月二期项目开始投入使用。

公司位于呼和浩特市、包头市、鄂尔多斯市“金三角”开发区中心地带,辐射内蒙主要人口密集区与工业密集区,与格林美位于河南兰考到山西长治的电子废弃物基地形成从中原到西北部的回收链,强化格林美在中原与西北部报废电子电器回收利用的核心地位竞争力与盈利能力。

河南新创资源再生有限公司位于内蒙古自治区鄂尔多斯市达拉特经济开发区,成立于2014年3月,现为格林美股份有限公司的控股孙公司。注册资金962.786万元,内蒙古新创资源再生有限公司电子废弃物集中处理项目于2013年10月列入自治区废弃电器电子产品集中处理发展规划。2014年10月通过鄂尔多斯市环境保护局建设项目环境保护验收和废弃电器电子产品处理企业资格审查取得处理资格证书。并于2015年8月被纳入国家基金补贴名单。

总投资9000余万元,占地76.5亩,2015年10月一期项目投产使用,2017年1月二期项目开始投入使用。

公司位于呼和浩特市、包头市、鄂尔多斯市“金三角”开发区中心地带,辐射内蒙主要人口密集区与工业密集区,与格林美位于河南兰考到山西长治的电子废弃物基地形成从中原到西北部的回收链,强化格林美在中原与西北部报废电子电器回收利用的核心地位竞争力与盈利能力。

天津新创资源再生有限公司位于内蒙古自治区鄂尔多斯市达拉特经济开发区,成立于2014年3月,现为格林美股份有限公司的控股孙公司。注册资金962.786万元,内蒙古新创资源再生有限公司电子废弃物集中处理项目于2013年10月列入自治区废弃电器电子产品集中处理发展规划。2014年10月通过鄂尔多斯市环境保护局建设项目环境保护验收和废弃电器电子产品处理企业资格审查取得处理资格证书。并于2015年8月被纳入国家基金补贴名单。

总投资9000余万元,占地76.5亩,2015年10月一期项目投产使用,2017年1月二期项目开始投入使用。

公司位于呼和浩特市、包头市、鄂尔多斯市“金三角”开发区中心地带,辐射内蒙主要人口密集区与工业密集区,与格林美位于河南兰考到山西长治的电子废弃物基地形成从中原到西北部的回收链,强化格林美在中原与西北部报废电子电器回收利用的核心地位竞争力与盈利能力。

内蒙古新创资源再生有限公司位于内蒙古自治区鄂尔多斯市达拉特经济开发区,成立于2014年3月,现为格林美股份有限公司的控股孙公司。注册资金962.786万元,内蒙古新创资源再生有限公司电子废弃物集中处理项目于2013年10月列入自治区废弃电器电子产品集中处理发展规划。2014年10月通过鄂尔多斯市环境保护局建设项目环境保护验收和废弃电器电子产品处理企业资格审查取得处理资格证书。并于2015年8月被纳入国家基金补贴名单。

总投资9000余万元,占地76.5亩,2015年10月一期项目投产使用,2017年1月二期项目开始投入使用。

公司位于呼和浩特市、包头市、鄂尔多斯市“金三角”开发区中心地带,辐射内蒙主要人口密集区与工业密集区,与格林美位于河南兰考到山西长治的电子废弃物基地形成从中原到西北部的回收链,强化格林美在中原与西北部报废电子电器回收利用的核心地位竞争力与盈利能力。